About us

HANDAN MACHINE

prioritizes advanced engineering and precision design in the development of interlocking brick machines and concrete brick machines.

With 25 years of manufacturing experience and 13 years dedicated to the specialized design of brick-making equipment, Handan Machine is proficient in producing a diverse range of machinery, including concrete block machines and soil-based interlocking brick systems. Each unit is engineered for high efficiency, structural integrity, and consistent output quality to meet industrial standards and site-specific requirements.

.

A few things we’re great at

Handan Machine is a leading specialist in brick machines equipped with mold systems.

We also accept custom orders to manufacture machines capable of producing various types of bricks based on customer specifications. Our machines are designed to allow customers to produce their own bricks efficiently and with consistent quality.

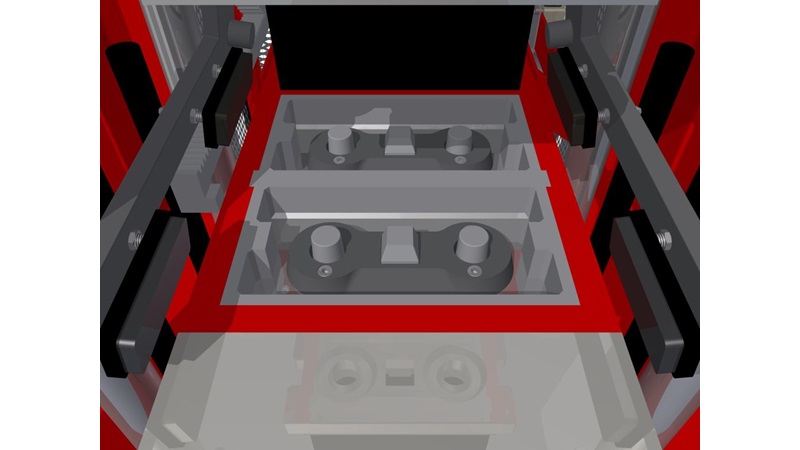

Interlocking Brick Machine

The Interlocking Brick Machine introduces an advanced method for producing high-performance soil-based interlocking bricks.

The system utilizes a controlled mixture of red soil or yellow soil, sand, cement, and water, which is then compressed under a hydraulic pressure of 15 to 30 tons. This high-compaction process results in bricks with superior compressive strength, dimensional accuracy, and enhanced durability suitable for load-bearing and weather-resistant construction applications.

Concrete Brick Machine

The Concrete Brick Machine is a hydraulically operated system that utilizes both vibration and hydraulic compaction to produce high-quality cement bricks, sand bricks, concrete blocks, hollow blocks, and interlocking pavers.

The machine is equipped with an integrated sand hopper, gravel hopper, belt conveyors, pan mixer, automatic pallet feeder, hydraulic control unit, manual hydraulic operation handles, roller conveyor, and transport trolleys. It supports interchangeable molds, allowing the production of bricks and blocks in various sizes and designs to meet diverse construction requirements.

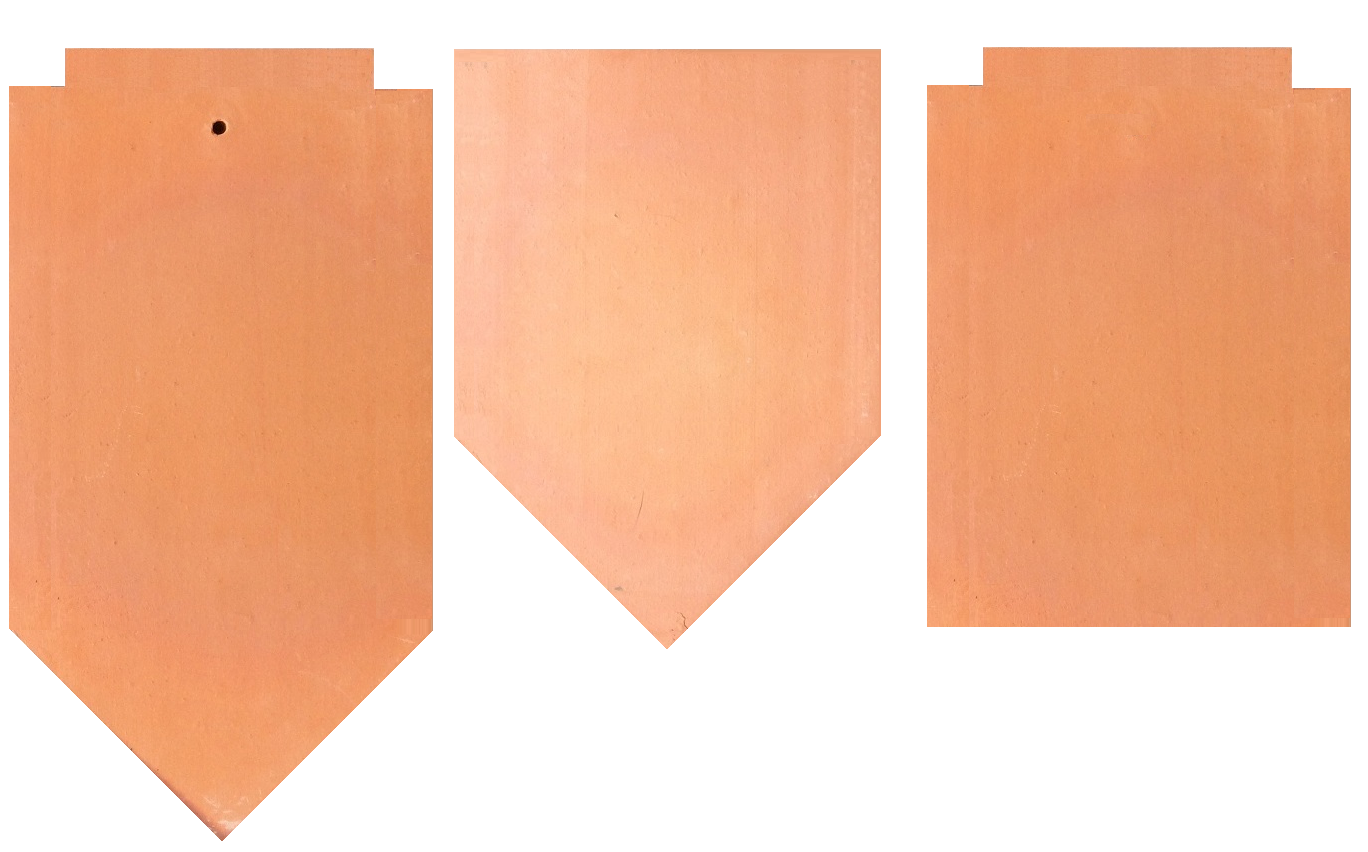

Teracotta Roof Tile

Terracotta roofing is engineered to perform reliably under diverse weather conditions while offering lasting aesthetic appeal.

In addition to being fire-resistant, terracotta tiles provide excellent UV and frost resistance. The non-corrosive materials ensure long-term durability without fading, while their low thermal conductivity enhances indoor comfort, particularly during hot summer months.

A wide selection of terracotta roof profiles and colors is available to suit various architectural styles and design preferences. Modern advancements in roofing technology have further expanded the possibilities, enabling greater creativity, flexibility, and performance in roof design.

High Production Efficiency

High Throughput:

Equipped with a powerful compression system, the machine is capable of producing a high volume of bricks within a short cycle time. This exceptional output capacity makes it ideal for meeting the demands of large-scale construction projects.

Energy Efficiency:

Incorporating advanced energy-saving technologies such as regenerative hydraulic systems and optimized power management, the machine significantly reduces energy consumption. This not only lowers operating costs but also enhances environmental sustainability, making it both eco-friendly and economically efficient.

Customizable and Modular Design

Flexible Molding System:

The machine features a versatile molding system capable of producing various brick types—including solid, hollow, and interlocking bricks. Quick-change, interchangeable molds enable seamless transitions between designs, minimizing downtime and maximizing operational efficiency.

Modular Components:

Designed with a modular architecture, the machine allows for easy customization, upgrades, and scalability according to evolving production requirements. This adaptable design ensures long-term value, making it a future-ready investment for growing operations.

What are you waiting for?

TAKE HOME OUR BRICK MACHINE FOR YOUR BUSINESS OPPONITIES

Our Clients

Contact us

For more detail

High Production Capacity

Cost-Effectiveness will reduced Labor Costs and Lower Production Costs

Environmentally Friendly

Reducing waste and minimizing environmental impact

Versatility and Customization

Variety of Brick Types and Adjustable Molds

Easy Operation and Maintenance

User-Friendly Interface and Durable Design